Broaching and keyseating are methods used to create keyways, splines, and other features in the internal diameter or bore of a gear. Keys and keyways or splines are used on gear IDs along with keyslots or splines on associated shafts. This prevents the gear from rotating on the shaft, allowing for greater torque transmission.

Gear Motions uses state-of-the-art horizontal and vertical broaching machines and keyseaters to ensure quality and precision on every gear for low or high volume runs. Contact us to speak to one of our sales engineers about how we can help with your next gear manufacturing project.

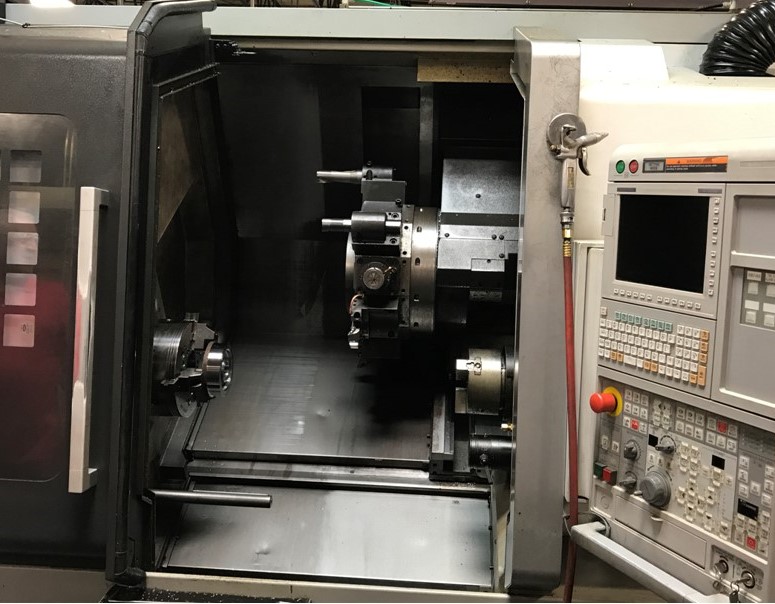

Broaching & Keyseating Machinery

- (1) Ohio Horizontal Model 10-60, 10 Ton

- (1) Mini-Broach Model A, 1 Ton

- (1) Colonial Horizontal Broach Model HAS-15-72, 15-Ton

- (1) Davis Keyseater

- (2) Mitts & Merrill Keyseater: 3A, 6HFR-KS

- (1) Oil Gear 20-Ton, 64″ Stroke Horizontal Broach

- (1) Mini-Broach 20-Ton, 64″ Stroke Horizontal Broach

- (1) Ty Miles MBLD 10-36-60, 5-Ton Vertical Broach

- (1) Ty Miles MBLD 4-24-150, 2-Ton Vertical Broach