At Gear Motions, we have been cutting gears since our inception. It has been part of our foundation since the very beginning, and today we continue to provide industry-leading gear cutting services as part of our full-service gear manufacturing offerings.

Our gear hobbing and gear shaping equipment can accommodate both small and large diameter gears. Capabilities include spur, helical, bevel and worm gears, as well as multiple types of sprockets, timing pulleys, shafts and splines.

Regardless of the size of your order, our gear manufacturing network is able to complete your gear cutting projects quickly and effectively. In fact, we continually make investments in top-of-the-line gear manufacturing equipment to ensure we are able to meet and exceed our customers’ needs. You can rely on consistent quality and service every step of the way.

Contact us to discuss your gear cutting needs with our experienced team today.

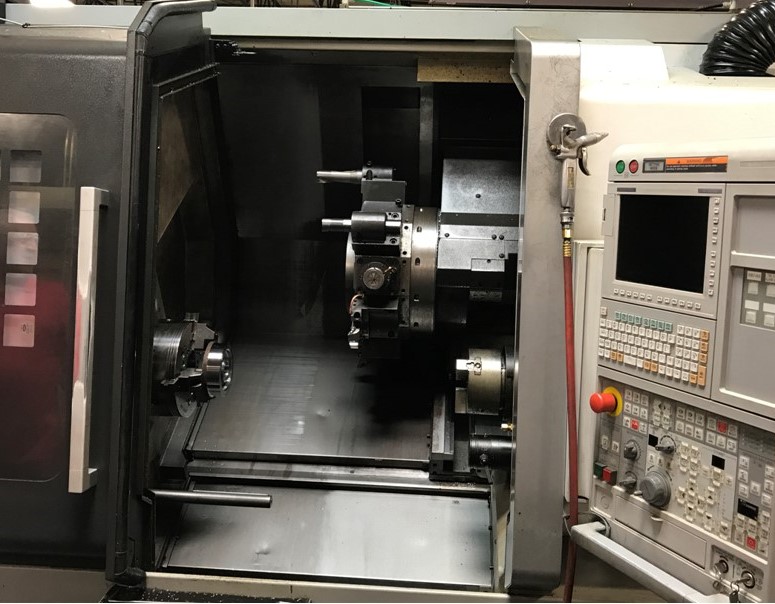

Gear Cutting Machinery

- (1) Gleason Genesis 400H

- (1) Liebherr LC380

- (1) Gleason 782 G-Tech 6 Axis

- (1) Mitsubishi GC20

- (1) Mitsubishi GD20

- (1) Mitsubishi GE15A

- (1) Koepfer 200 with Automation

- (2) 16″ Pfauter P400

- (1) 24″ Pfauter P630

- (1) 36″ Pfauter P900

- (1) 60S G&E Gasher

- (2) Richardon R200 CNC

- (6) Barber Coleman from 6″ to 16″

- (1) Wolf GH20-11D

- (1) Fellows No. 4AGS

- (2) Fellows No. 36

- (2) Gleason 14A Straight Bevel Gear Generator

- (1) Gleason 24A Straight Bevel Gear Generator

- (1) Gleason 104 Straight Bevel Gear Generator