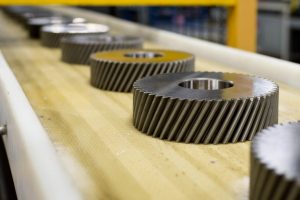

In precision manufacturing, grinding is often where quality is won or lost. Tight tolerances, surface finish requirements, and repeatability all converge at this stage of the process. As part complexity increases and customer expectations continue to rise, advanced grinding technology becomes essential.

Expanding Our Grinding Capabilities

The Studer S151 is designed for high-precision external and internal cylindrical grinding, particularly for small- to medium-sized, complex components. Its flexibility and accuracy make it a strong fit for the tight-tolerance work required across many Gear Motions applications.

Key capabilities include:

- High-precision grinding to meet demanding tolerance and surface finish requirements

- Flexible configurations that support a wide range of part geometries

- Advanced control systems that improve repeatability and process stability

- Rigid machine construction that supports long-term accuracy

This addition expands our ability to deliver consistent, high-quality results while supporting both production and specialized applications.

Supporting Continuous Improvement

Investing in advanced equipment is a core part of how Gear Motions strengthens process control and manufacturing consistency. The Studer S151 enhances our grinding operations by improving accuracy, reducing variability, and increasing confidence in final part quality.

manufacturing consistency. The Studer S151 enhances our grinding operations by improving accuracy, reducing variability, and increasing confidence in final part quality.

For customers, this means:

- More consistent performance from part to part

- Greater reliability in demanding applications

- Manufacturing processes designed to support long-term quality

Proven Technology, Integrated into Our Process

Studer machines are recognized for precision, thermal stability, and reliability in challenging grinding applications. The S151 brings these strengths into our shop, allowing us to integrate proven grinding technology directly into our production flow.

Studer machines are recognized for precision, thermal stability, and reliability in challenging grinding applications. The S151 brings these strengths into our shop, allowing us to integrate proven grinding technology directly into our production flow.

The result is a grinding platform that supports current requirements while providing flexibility for future needs.

Looking Ahead

The addition of the Studer S151 strengthens our ability to deliver consistent, high-precision results today while supporting evolving customer requirements in the future.

If you’re evaluating suppliers for precision-ground components, we welcome the opportunity to demonstrate our process controls and quality capabilities.